In 1995 hot melt adhesive (HMA) was aggressively introduced to sport shoe making industry. Different types of hot melt adhesives (SBC, EVA, APO-based HMAs, Polyesters, Polyamides and PUR) are used for bonding specific shoe components.

Basically, these adhesives are applied in three major process rooms: parts preparation, shoe upper stitching, and upper-sole assembly. Some parts with pre-coated adhesives are supplied from outsourcing coater/laminators.

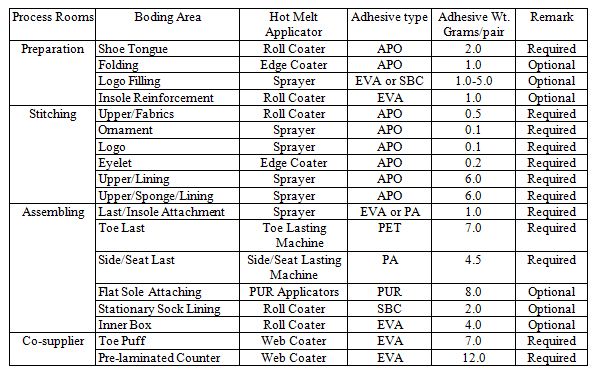

The following table lists the bonding areas, type of applicators, type of adhesives, and typical application weight per pair of shoes.

It is worthwhile mentioning that PUR is currently only used for bonding flat soles of running shoes with a PUR roll coater. Other shoes with complicated shoe soles and side walls will require a very sophisticated 3D PUR sprayer or brusher.

The PUR applicator should not under and over coat PUR at all bonding surfaces. Technically, there is no problem to apply PUR to bond any shoe soles regardless of sole materials and shapes. The investment in this non-contact PUR application technique for bonding various shoe soles and side walls is typically too high to afford for sport shoe manufacturers.