Low-pressure overmolding is a process by which hot melt adhesives can be injected into a mold to chemically bond to polyurethane parts. The applications for this process are numerous, and largely involve working with delicate parts that need to be protected from the elements or various kinds of shock — thermal, kinetic, etc.

For example, you may need to protect an antenna within some type of housing. A low-pressure injection overmold can hold the fragile antenna in place, protect it from environmental factors like moisture or temperature fluctuations, and provide a layer of protection from drops and impact damage.

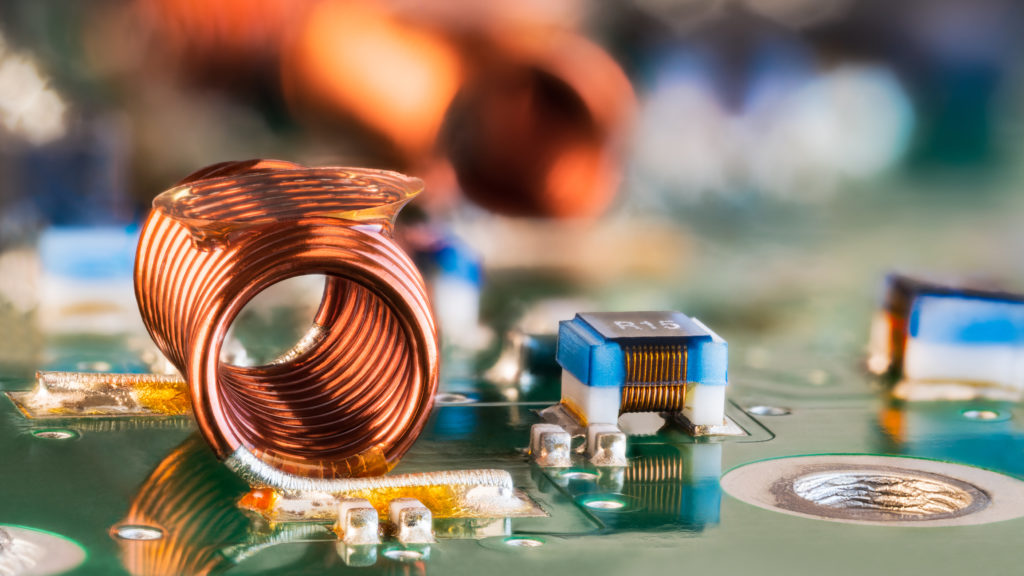

Because the process is both low pressure and low temperature, otherwise sensitive components can be encased in a protective layer without damaging the internal parts. This also means items within computer cases or other sensitive electronic products can be secured without creating messy or unstable attachment points within housings.

These are some of the benefits of Overmolding:

- Enhanced protection for fragile items —Because low pressures are used in in the overmolding process, delicate components like electronics can be encased in protective material without being damaged. Once the fragile item is molded into the part, it has increased protection due to the layer of durable material surrounding it. This makes it so the component can function safely even in wind, water, or rapid motion.

- Reduced parting lines — By molding an item into a part rather than using primers and adhesives to fuse two parts together, unsightly seams and molding lines are completely eliminated. Low-pressure overmolding makes for a smooth and flawless item.

- Wireless capabilities — Overmolding also creates parts that have strong wireless capabilities. Low density of overmolded materials reduces interference in the radio signal of wireless components compared to other methods like potting.

- Prevention of theft and tampering — Low-pressure overmolding helps prevent both physical and intellectual property theft. Because parts are seamlessly molded into a part, tampering with the component without breaking it is much more difficult. This means sensitive electronics are better protected from physical theft and industrial espionage.

Overmolding Materials

Glue Machinery Corporation offers a wide variety of injection molding materials. The process starts with two liquid thermosetting polymers that are combined to chemically react and expand as they fill the shape of the mold. This results in a durable, flexible, lightweight component. By using different polymers, the end product can be made to be:

- Solid and inflexible

- Elastic and stretchy

- Rigid foam that breaks when bent

- Flexible foam that can be reshaped with pressure

Glue Machinery offers several different polymer materials to suit your needs as well as the equipment to handle your injection molding needs.

Contact GMC or give us a call at 410.264.1818 if you have questions about how we can help you meet your injection molding needs.